Recent service calls – June

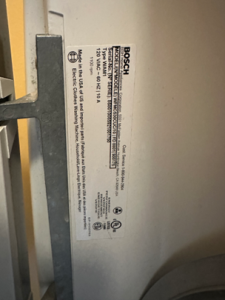

Recently an old customer of ours called in and requested service for 20 year old Bosch washing machine that was not completing cycle. After arriving on site and talking to customer it was confirmed that washing machine would complete some cycles but usually stops mid cycle or towards the end of cycle and shows an error message 13. Customer also advised that when washer stops, water is not drained or not drained completely. After a quick search of the error it was determined that error 13 pertains to washer not being able to drain water in appropriate time. First thing in this situation was to drain the washer manually to access coin trap of the washer to check for obstructions. After quickly removing water using shop vacuum coin trap was removed to find no obstructions or debris. While coin trap removed, technician checked drain pump impeller for excessive play and confirmed that impeller is in fact loose which causes intermittent drain issue. After receiving confirmation from customer, new drain pumps was ordered and installed the following day.

This customer called in regarding their compact Samsung dryer not heating. Customer advised that dryer turns on and rotates but does not heat up. When technician arrived on site the dryer was found stacked on top of washer and away in a closet. This type of dryer has resettable thermostat located on heating element housing. Once washer and dryer was pulled out, technician removed the cover and confirmed that resettable thermostat in fact open. After resetting the thermostat heating started working but reason for it to trip is not what you might think. The usual reason for this thermostat tripping is blocked exhaust vent which makes dryer run too hot. In this particular case the reason was faulty idler pulley. Pulley seized up and was not rotating causing the belt to drag and in turn slow down the drum which caused poor venting. Pulley was replaced with newer version of the part containing ballbearing to prevent future issues.

If you are experiencing any issues with any of your appliances, do not hesitate to contact Tricity Appliances Quality Service and we will be glad to set up an appointment to repair your appliance as soon as possible.

You can reach us by phone at 778-488-0397 or fill out online service request form on our web site www.tricityquality.com